Details:

Oxyhydrogen generator OH1500

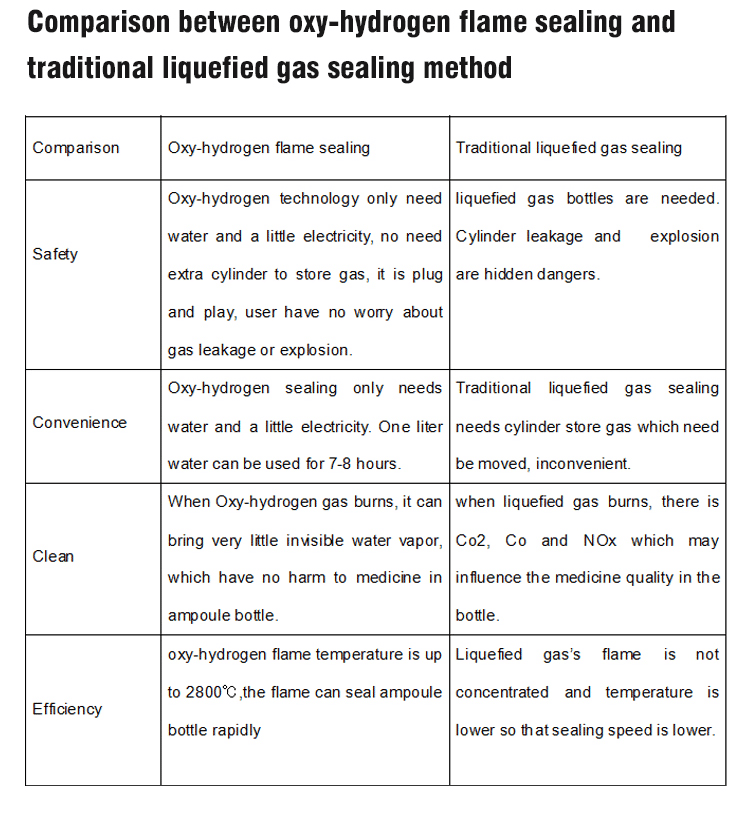

The traditional ampoule sealing machine adopts liquid gas as fuel and air as combustion-supporting gas.The produced flame contains carbon dioxide,carbon monoxide and nitrogen compounds.These substances will impact on the quality of pharmaceuticals and bring hidden dangers to working environment.

Okay Energy Oxy-hydrogen generator mainly electrolyzes water to hydrogen and oxygen, and form oxyhydrogen flame.The temperature of oxyhydrogen flame is as high as 2800 degree so that the oxyhydrogen sealing effect and speed is higher and faster than traditional oxyfuel gas for ampoule sealing.

Oxyhydrogen flame for ampoule filling and sealing:

1.Safety. no gas bottles. and no gas leakage or explosion.

2.Convenient. 24hours continous running working.Only consume some water and electricity.

3.Clean. Oxyhydrogen flame burns without Co2, Co and NOx which may influence the medicine quality.

4.High efficiency. the sealing speed is fast than the traditional liquid gas.

- Decrease Fuel Consumption

- Increase Power

- Reduce Exhaust Emissions

- Extend Engine lifetime

- Eliminate Carbon Deposits

Technical Parameters:

|

Model Number

|

OH1500

|

|

AC Voltage Requirement

|

380V

|

|

Phase

|

three phase

|

|

Rated Power

|

4.5 kw

|

|

Max. Gas Output

|

1500L/h(adjustable)

|

|

Max. Working Pressure

|

2 kg/cm2

|

|

Max. Water Consumption

|

0.9 L/h

|

|

Water Feed

|

auto

|

|

Dimensions - L*W*H

|

1070*670*1000mm

|

|

Gross Weight

|

200kg

|

|

Ventilation Space Requirement

|

400mm in each direction

|

Advantage characteristics:

Related Accessories: