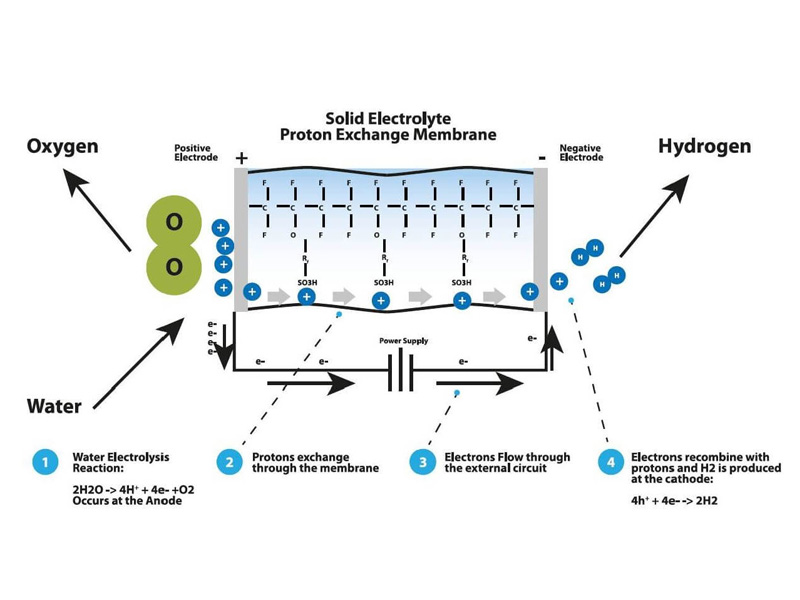

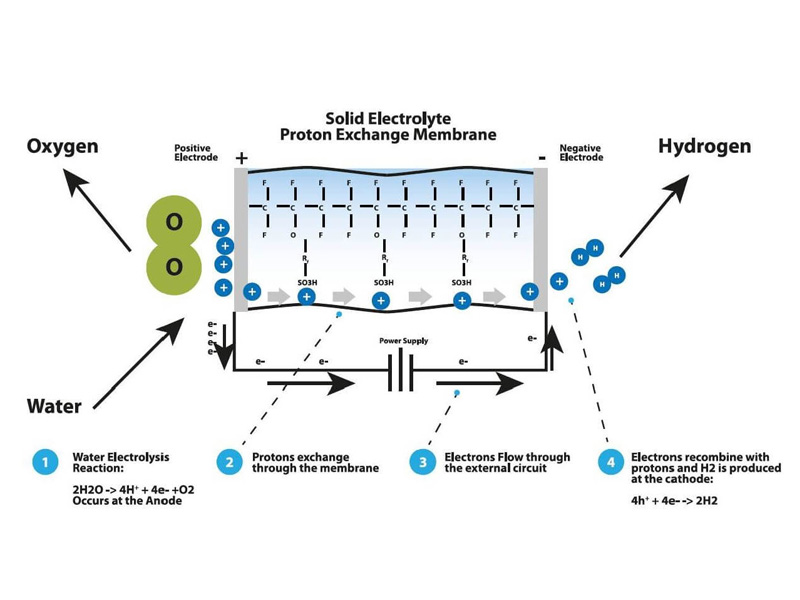

The PEM hydrogen generator has the main three parts including PEM pure water electrolyzer, gas and water separator, control module. The generator electrolyzes pure water or deionized water through electrolytic cell to produce hydrogen and oxygen gas, in which the volume ratio of hydrogen and oxygen is 2:1. The resistivity of water required shall not be less than 1m Ω· cm. The output volume of H2 can be 150ml/min,300ml/min,600ml/min,1000ml/min,1500ml/min, 2000ml/min.

How to choose a hydrogen generator?

Hydrogen supplied by an on-site hydrogen generator is the safer and cost-effective alternative to pressurized cylinders. If you are to buy a hydrogen generator,you should think about its purity,flow rate,and pressure. For example,you want a hydrogen generator for gas chromatography in the lab.

How to do maintenance?

The machine maintenance is about the washing requirements of water tank and water exchange.The water tank should be kept clean. Even if the soft water is used for a long time, there may be microorganism breeding, which will make the water turbid and affect the gas production and service life of the electrolyzer. After 2 months of running, the water in the tank should be released from the drain pipe, and the tank should be washed for several times. Then the disinfectant was sprayed with medical alcohol. After adding proper amount of fresh water, the machine was swayed several times before and after the machine. The water was discharged and washed repeatedly with deionized water for at least 3 times. The drain pipe of the water tank is attached to the back baffle of the instrument and can be taken down or put in freely.