Polishing and Sealing

The oxy-hydrogen flame temperature is up to 2800 ℃.It can polish the acrylic sheet rapidly,seal ampoule quartz glass very fast,which widely used in the field of university,laboraratory,pharmaceutical factory. The quality and speed of oxyhydrogen flame polishing and sealing is higher than liquid gas's.

View More +

Welding and Brazing

Oxy-hydrogen welding machine adopts patented hho technology to electrolyze water to H2 and O2 gas on demand,no gas cylinders. The mixture oxyhydrogen gas is output to welding torch through safe device, and fire them to form oxy-hydrogen flame for precise and fast welding.

View More +

Cutting

Oxyhydrogen flame cutting machine can be widely used in carbon steel cutting industry,shipyard,steel structure processing plant and continuous casting slab cutting of steel plant.It can cooperate with manual cutting torch, semi-automatic cutting machine, shape cutting machine, CNC cutting machine to instead of traditional fuel gas.

View More +

Fuel Saving

HHO fuel saving for boiler,waster incinerator,diesel generators is used as combustion-support,which has changed the traditional combustion way and significantly reduced carbon emission and the fuel consumption.

View More +

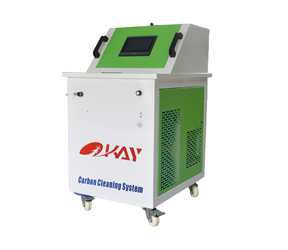

Engine Carbon Cleaning

Oxyhydrogen engine carbon cleaning machine consumes water and electricity to create oxy-hydrogen gas which feeds into the engine for elimination of the carbon build-up,decreasing the fuel consumption and increasing the power performance.

View More +

Catalytic Converter Cleaning

Visible catalytic converter cleaning machine is an effection solution for solving the problem of excessive car exhaust emissions caused by the catalytic converter malfuction.

View More +

Wax Investment Casting

During making max pattern,the oxy-hydrogen generator is the ideal equipment for the lost wax casting process and wax pattern build up.The oxyhydrogen flame is concentrated and adjustable, it can achieves precise wax casting.

View More +

Laboratory Ultrapure and Pure Water

Laboratory pure water system delivers two quality water,type3 RO water and type 1 ultrapure water,which is free of impurities, of consistent quality and always available upon demand for experiment analysis.

View More +

.jpg)